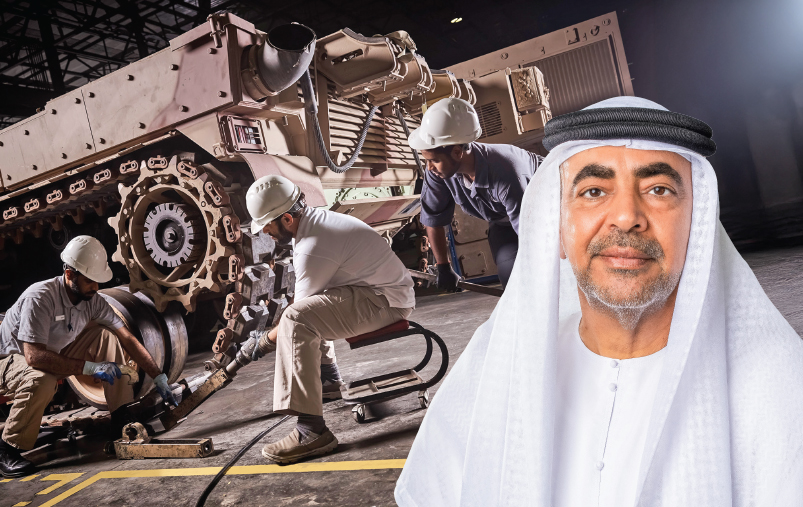

The defence maintenance, repair and overhaul (MRO) industry is transforming to leverage technological innovations and adapt to the demands of the changing security landscape. Regular maintenance to prolong the operational capacity of vital assets no longer depends on skilled technicians alone. To reduce downtime and streamline workflow, OEMs and MROs are implementing the latest systems and state-of-the-art engineering processes through the use of Artificial Intelligence (AI), real-time monitoring, cloud technology, Internet of Things (IoT), and other complex programs to predict maintenance and ensure long-term reliability of vital equipment.

Land MRO

One of the key strengths of a nation lies within the ability of its defence system to protect itself from current and imminent threats, along with various other factors such as economic stability, technological advancement, political system, and foreign relations with other nations. The defence system is made up of military forces that involve both personnel and defence equipment. At the core of this is maintenance, repair, and overhaul for armoured and other essential land military vehicles. MRO guarantees the operational readiness, reliability, and performance of these platforms for any kind of mission. The main objective of MRO is to ensure that vital defence assets are at their best state of readiness without increasing costs while maintaining maximum availability.

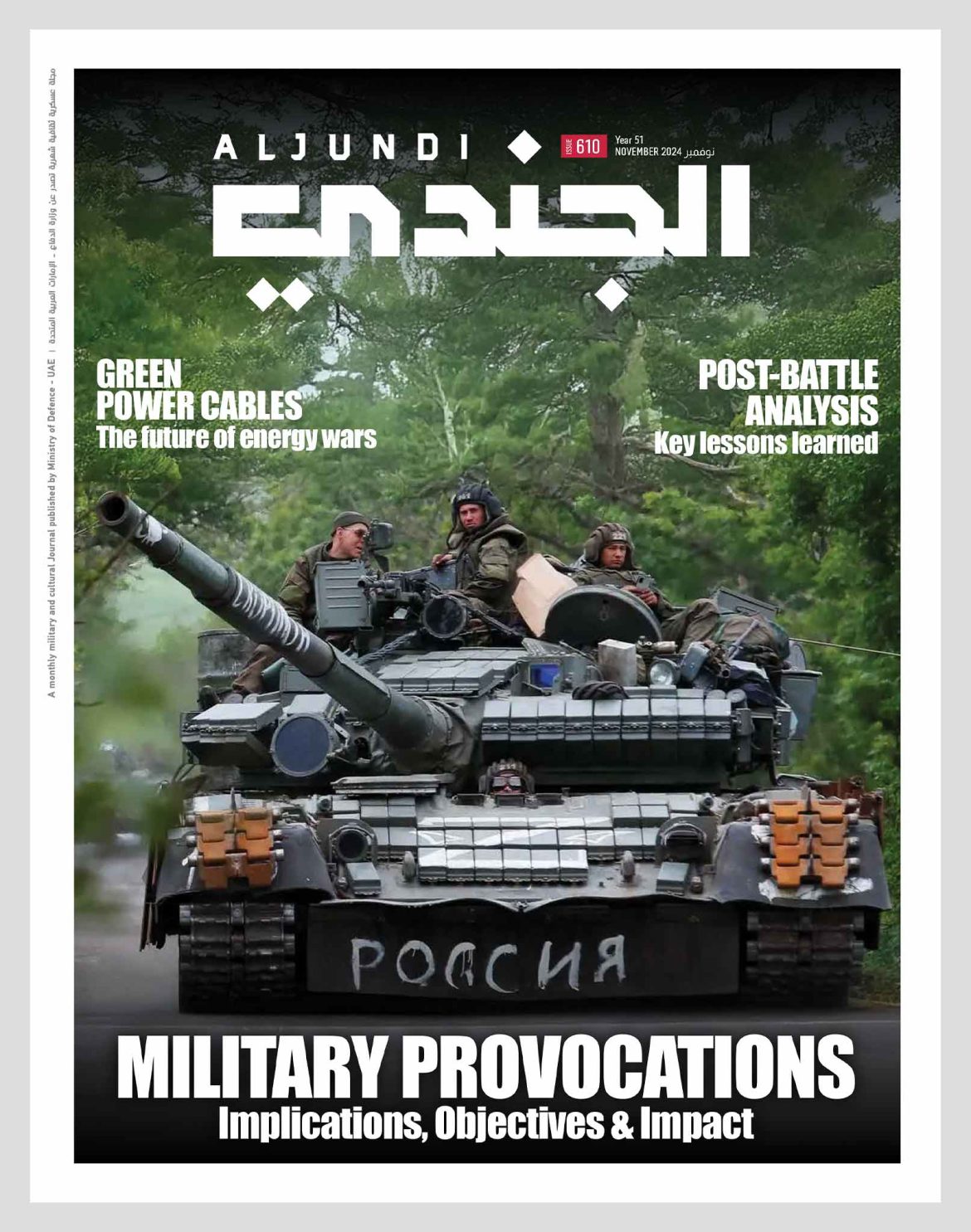

Land platform MRO market insights

The world’s defence land platform MRO market is estimated at USD 44.85 billion in 2024, according to Global Information Insights. It is projected to grow to USD 71.43 billion by 2034. This positive market growth is due to the increase in the budget of the world’s defence industry because of current geopolitical tensions in various regions around the globe, the adoption of smart technologies, military modernisation, land forces expansion, and a growing focus on sustainability to maximise resources and improve operational efficiency to reduce costs.

Technological developments and their impact on MRO

Technological developments and their impact on MRO

By integrating the latest systems, MROs and OEMs can prolong their lifespan, make critical decisions based on data, allow faster turnaround times during maintenance cycles, and increase the operational availability of vital assets. Technology improves the performance of the asset itself as well as MRO operations and its maintenance workloads. Moreover, it maximises the productivity of personnel involved behind the scenes who work tirelessly around the clock such as technicians, engineers, and other specialists.

Furthermore, other available technologies that the MRO industry has embraced include:

Streamlined Communication: Communication among teams is streamlined and carried out seamlessly without the need to physically check the land platform itself. With the use of sensors, data can be sent through secure servers with the aid of specialised optical equipment such as CCTVs, drones, cameras, videoscopes, borescopes or fiberscopes.

Internet of Things (IoT) and Cloud Computing: IoT and cloud technology enable continuous equipment monitoring by maintenance personnel, which can be done remotely. Using state-of-the-art condition monitoring technologies like sensors and communications networks, data is collected and transferred to cloud-based servers to assess the state of equipment. This enables MRO personnel to gather data and analyse it in real-time to proactively determine current, impending, and potential issues, allowing specialists to troubleshoot before the problem becomes harder and more expensive to manage. Moreover, by initiating specific repairs and optimising maintenance schedules, MROs can avoid major fixes that lead to a longer downtime.

Robotics and AI: Breakthroughs in robotics and AI allow visualisation of hard-to-reach places of land-based platforms. Moreover, it enables technicians to inspect equipment remotely using tablets and high-definition cameras. Additionally, they can use drones and CCTV cameras and send video feeds via secure networks to be stored on the cloud.

CMMS: Centralised maintenance management systems (CMMS) have evolved from simple to more complex systems, allowing the integrated management of staff, tools, and operations into one platform for more accessible and more organised data storage, processing and storage capabilities of computing devices.

Augmented Reality and Virtual Reality (AR/VR): The use of augmented reality and virtual reality has dramatically transformed the way maintenance teams are trained. This technology allows for training sessions to be conducted via video conferencing, enabling remote training for trainees. Additionally, virtual models and field tours can now be utilised without the need for printed learning materials or long-distance travel to attend training sessions, especially for complex systems.

Robotics: Robots can mitigate risks when a potential hazard is involved, completing tasks such as vehicle inspection, dangerous materials handling, and replacements of components, improving the safety of personnel and the general work environment. Moreover, various other cutting-edge technologies are being implemented within the MRO industry and many more are continuously being developed as the industry embraces modern equipment, applications, and systems.

Challenges

First, the rising cost of MRO can present challenges because system and hardware upgrades are not cheap. Geopolitical tensions can also present supply issues for replacement parts that require procurement of raw materials through complex logistics.

Second, the more cutting-edge the equipment and systems are, the more highly specialised technicians and MRO specialists are needed. This requires continuous training to cope with the latest technology and systems in the land platform MRO sector. Lastly, as MROs adapt to technological advancements, compliance with various regulations and safety standards is necessary, which leads to higher cost of MRO components.

The future of MRO

The future of land platform MRO looks promising because of the trajectory of the market growth as nations transform and invest in the life-cycle management of their defence fleet. Global military force expansion and modernisation not only accelerate the growth of the market but also ensure that land platforms are running optimally and properly maintained, ultimately protecting lives and strengthening national and global security. In the long run, the adoption of land platform MROs to the latest technologies and effective practices greatly reduces long-term operational costs., leading to greater efficiency and reduced downtime.

Additionally, the advantages of modern innovations underline the necessity of land platform MROs investing in the latest systems and equipment despite the challenges, especially at a time when heightened geopolitical tensions are driving military forces to expand, upgrade their assets, and ensure mission readiness. .●